UPMSat-3

UPMSat-3 is a university-led microsatellite initiative managed by the “Ignacio Da Riva” Institute for Microgravity Research (IDR/UPM) at the Universidad Politécnica de Madrid. This satellite marks the next step in the UPM’s satellite series, following UPMSat-1 & UPMSat-2.

UPMSat-3 aims to design, manufacture, qualify, launch, and operate a cost-effective satellite for technological demonstration and educational and scientific purposes. This project enhances UPM’s position in aerospace technology, providing a unique platform for research and innovation.

Technical characteristics

Separation system

More about UPMSat-3

More than 50 people participate in UPMSat-3, including professors, students, technical, and administration staff. In addition to the IDR/UPM researchers from the de la School of Aeronautical and Space Engineering (ETSIAE), other UPM research groups are collaborating to contribute with their knowledge and experience in specific areas needed for the development of UPMSat-3: researchers from the Real-Time Systems and Architecture of Telematic Services (STRAST), which already participated in UPMSat-2, and from the UPM Radiation Group, and researchers from the ETSII UPM.

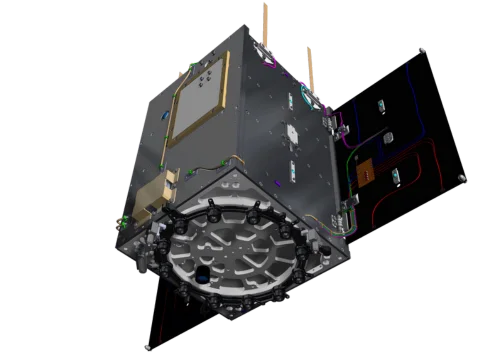

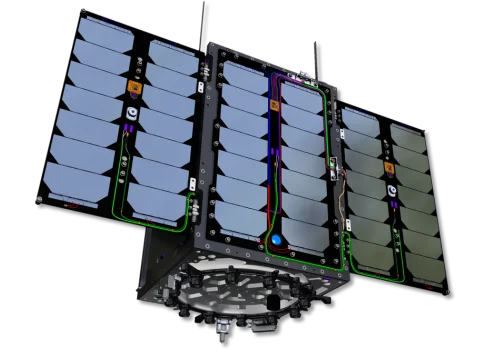

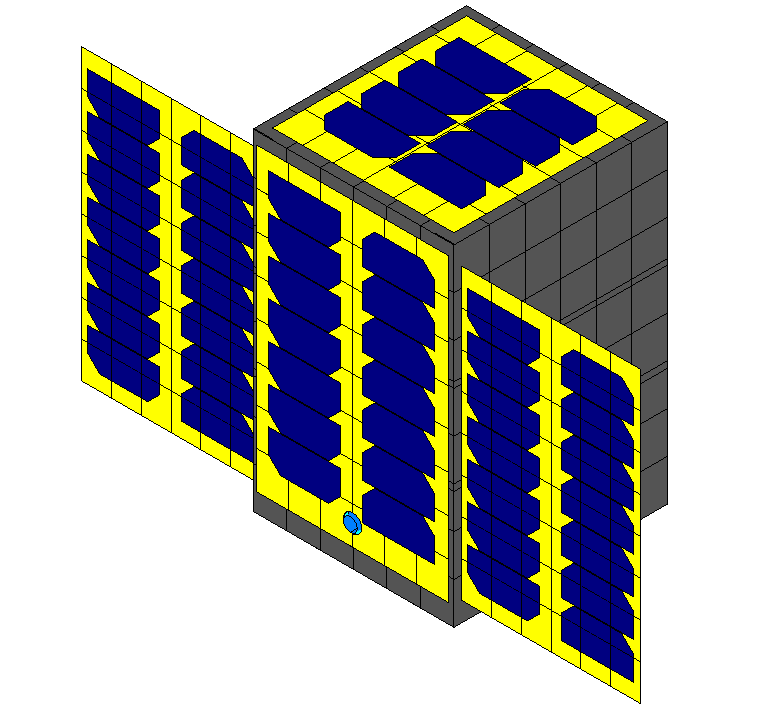

Weighing up to 22 kg and with dimensions of 250 x 250 x 366 mm³, UPMSat-3 will operate in a sun-synchronous orbit at 500 km altitude, with a 10:30 local time of passage.

It introduces advancements over previous models, including three-axis attitude determination and control and deployable solar panels using shape-memory mechanisms. Beyond its core role as an educational platform, UPMSat-3 will validate industry and university technologies in space, strengthening IDR/UPM’s collaboration with the amateur radio community and contributing to citizen science through AMSAT and SatNOGS. The project will also engage the public and school students with initiatives like “SEND YOUR NAME TO SPACE” and videos such as “UPMSat-2: Beyond the University” and “I Want to Be an Engineer.”

The UPMSat-3 program is funded through various internal projects, support from several companies and the government of the Community of Madrid, support from the ETSIAE and UPM, and the OAPES project (Y2020/NMT-6427) within the 2020 Synergistic Program of the Community of Madrid.

The Launch

The IDR/UPM has successfully continued its small satellite development line, securing a launch opportunity at no cost through selection in the competition promoted by Germany’s DLR (Deutsches Zentrum für Luft-und Raumfahrt) and the European Space Agency (ESA). The UPMSat-3 mission will launch aboard ISAR’s SPECTRUM vehicle, scheduled for Q2-Q3 of 2025

The primary challenge for university space missions is the high cost of launch (typically between €1-2 million). This unique opportunity enables us to proceed with the UPMSat-3 mission.

The launch event is also a valuable opportunity to highlight our scientific activities in the media, capturing public interest and showcasing high student involvement. Additionally, it brings visibility to the sponsoring organizations, with representatives from Spain and the Community of Madrid expected to attend the launch.

UPMSat-3 in detail

The platform

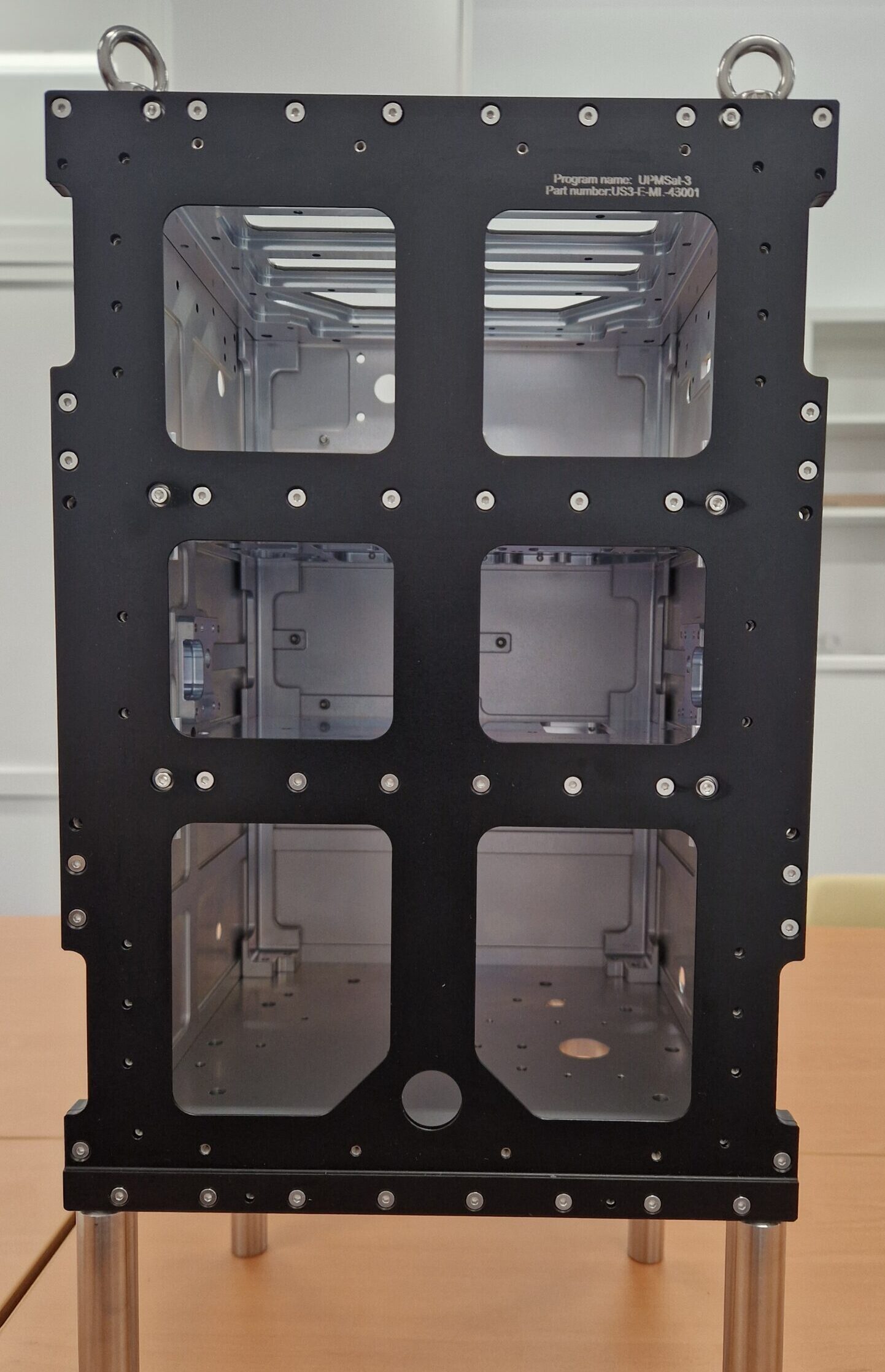

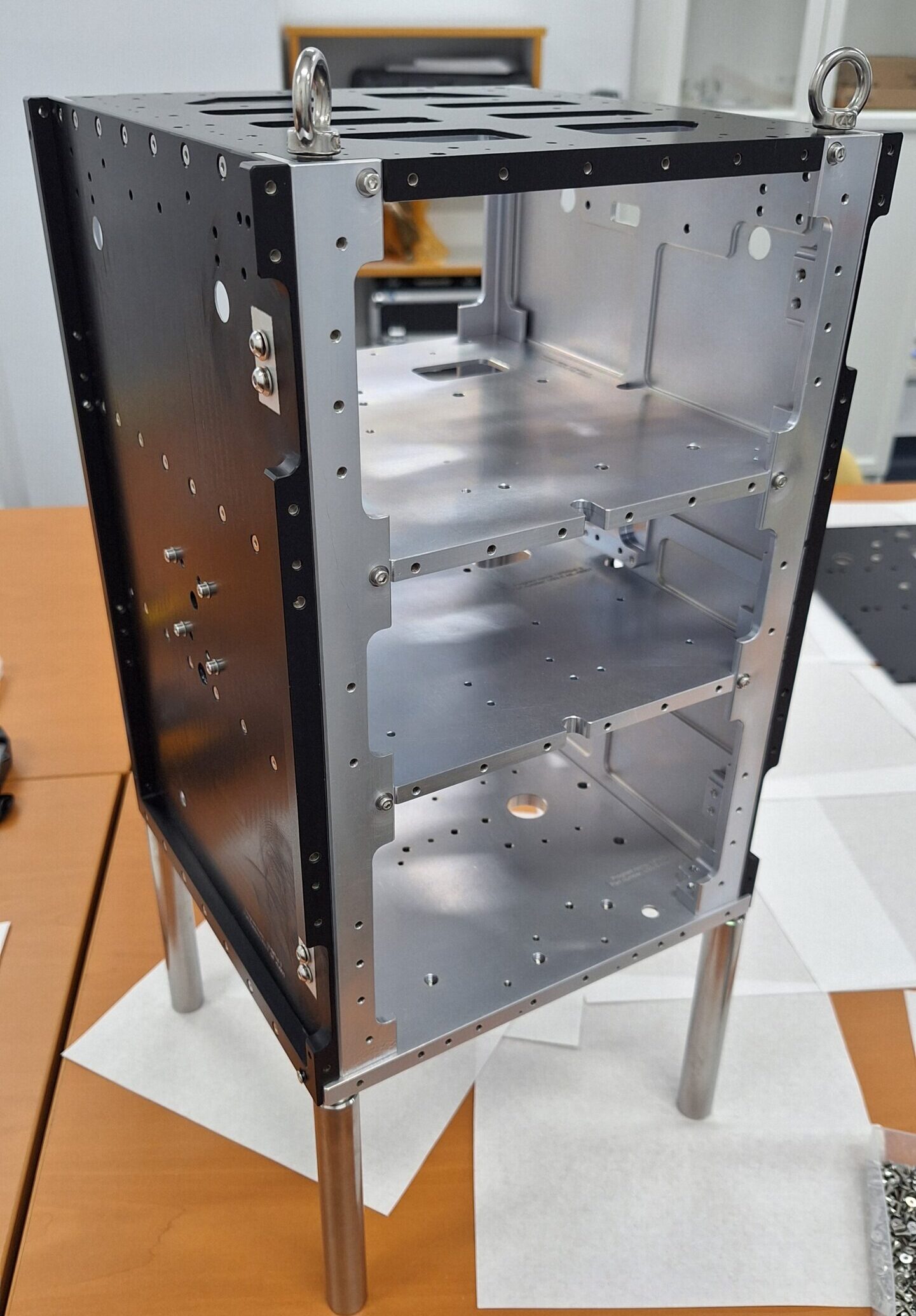

The structure of UPMSat-3, as in its predecessors, has been designed by the IDR/UPM mechanical design team. It is the element that provides mechanical and assembly support for the rest of the units and equipment that conforms the platform. It also ensures the geometrical and structural integrity of the system throughout its lifetime and particularly during launch.

The primary structure is made of aluminium 7075, with a modular configuration.

The UPM-Sat 2 primary structure, designed entirely in aluminium, has a modular configuration, consisting of four parallel trays joined at their corners by rods, forming a structural frame. Four flat panels enclose the structure at the sides. The trays are the main structural element. Most of the satellite’s components and subsystems are installed on them. They have been designed with an orthogrid-type structure, in order to reduce their mass without penalising their rigidity.

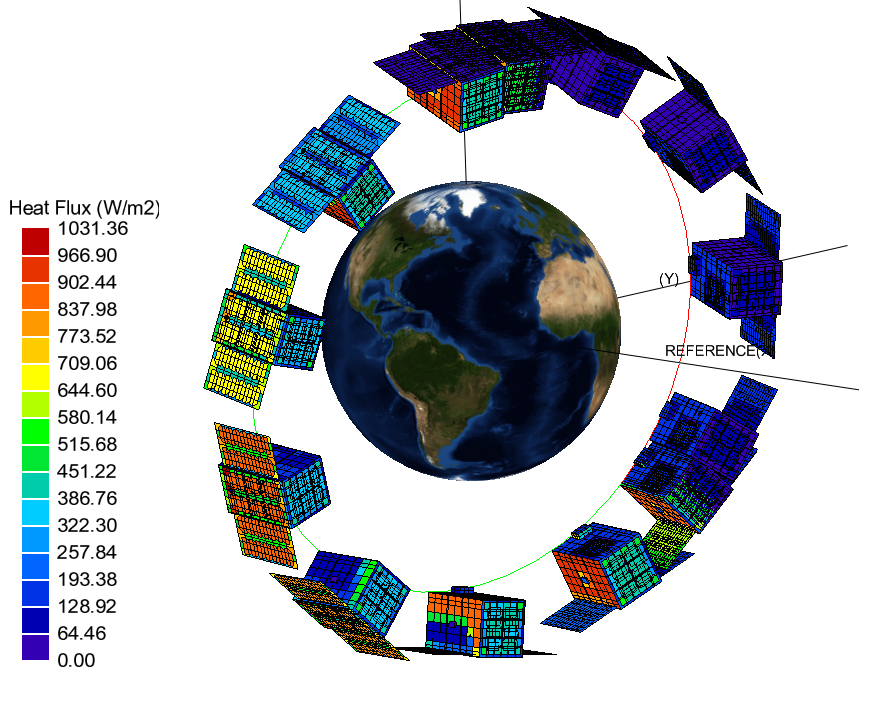

Thermal control

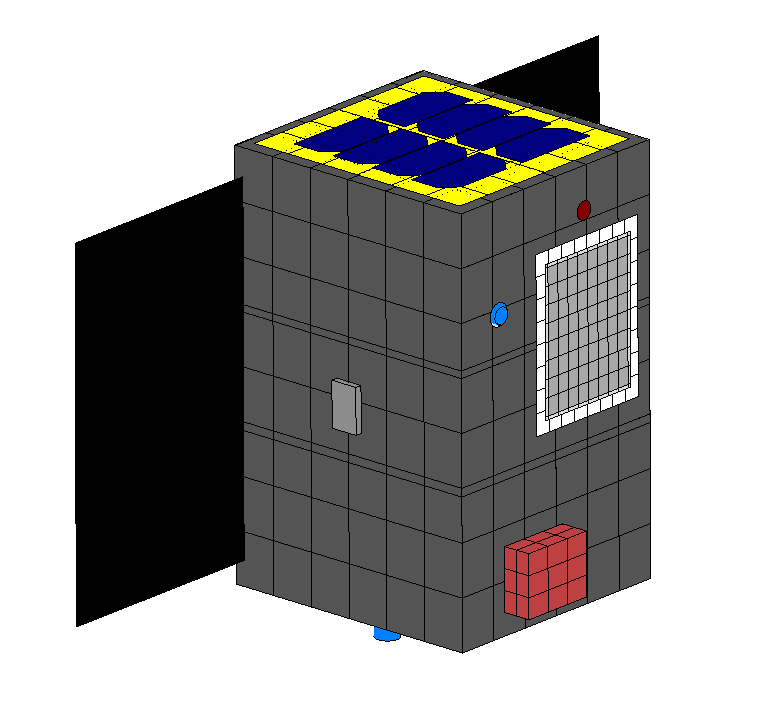

UPMSat-3 has a thermal control subsystem designed to ensure optimal performance of its components in the demanding space environment. This subsystem plays an essential role to keep the on-board instruments and systems within their operational and survivable temperature ranges.

The thermal control design was based on a thorough analysis of the thermal conditions of the satellite, and its sunsynchronous orbit at 500 km altitude, using ESATAN-TMS software. Surface finishes such as black anodised and SurTec 650 have been selected, whose thermo-optical properties have been measured using TESA2000. This tool helps to know the real properties of each surface treatment, improving the analyses carried out.

Among the solutions implemented, a radiator specifically designed to dissipate the heat generated by one of the payloads stands out. This radiator is isolated from the rest of the structure by means of a PEEK frame and attached to it by means of structural adhesive, which significantly reduces heat transfer by conduction. In addition, due to the compact dimensions of the satellite, a copper thermal strap had to be designed, which thermally connects the payload to the radiator to meet the thermal requirements.

To validate and refine the design, several tests have been carried out on engineering models, to correlate the mechanical joints of the thermal model with the experimental data obtained. These tests have been fundamental to adjust the critical parameters of the design and ensure its correct performance in the space environment.

In addition, qualification tests are currently being carried out on certain instruments, verifying their ability to operate in extreme temperature and vacuum conditions similar to those in space. The thermal control system combines passive and active strategies, such as PID-controlled heaters, to ensure that all components operate within their optimal temperature ranges.

Temperature signal conditioning unit

The aim of the Temperature Conditioning Unit for the UPMSat-3 microsatellite is to select and condition the analogue signals from the satellite’s temperature sensors to be read by the on-board computer (OBC). Also manages the thermal stabilisation of the satellite through heaters, trying to achieve a reliable, small and cost-optimised design. The implemented solution acts as a driver to acquire data from 27 temperature sensors, implement the interface with the OBC for routing and signal acquisition, manage the power supply of sensors and heaters, and provide the PID control interface for thermal stabilisation. Several units have been developed in the project for functional validation and under environmental conditions (vibration and thermo-vacuum).

Attitude control and determination

The Attitude Determination and Control Subsystem (ADCS) ensures that the satellite maintains the proper orientation to fulfil its mission. ADCS includes, for example, orienting the satellite according to the requirements of the on-board payloads for proper operation, or positioning the solar panels towards the Sun, ensuring optimal power generation.

Unlike its predecessors, UPMSat-3 is a three-axis stabilised satellite, with full control over its orientation. To achieve this capability in a reduced development time, CubeSpace’s commercial 3-Axis CubeADCS module, an advanced and reliable solution, has been integrated.

The ADCS system performs two main tasks:

- Attitude determination: this process allows to know/estimate the satellite’s orientation.

- Attitude control: This process involves executing the necessary actions to achieve or maintain the desired orientation.

Attitude determination is achieved by comparing the data obtained from the sensors on board the satellite with the reference values associated with a known orientation. UPMSat-3 is equipped with a combination of sensors, which ensures that its orientation is known at any point in its orbit, even during eclipse phases:

- Two magnetometers: main and redundant.

- A ‘coarse’ Sun sensor.

- Two visible spectrum cameras: one to estimate the direction of the Sun and one to identify the nadir direction (direction of the Sun towards the centre of the Earth).

- A star tracker that uses the stars to determine the satellite’s orientation.

To control its orientation, the UPMSat-3 has the following actuators:

- Three reaction wheels: one for each main axis, they are used to perform orientation changes quickly and accurately.

- Three magnetorquers: used mainly in the initial phases of the operation phase, for correct stabilisation of the satellite (detumbling) and, later, to assist the reaction wheels or to desaturate them when necessary.

In addition to all the features mentioned above, UPMSat-3 also incorporates attitude determination and control algorithms created by IDR/UPM itself with the idea of testing and validating its operation in space.

Expected orbital parameters 21/03/2025, 12:00 UTC

Data management and embedded software

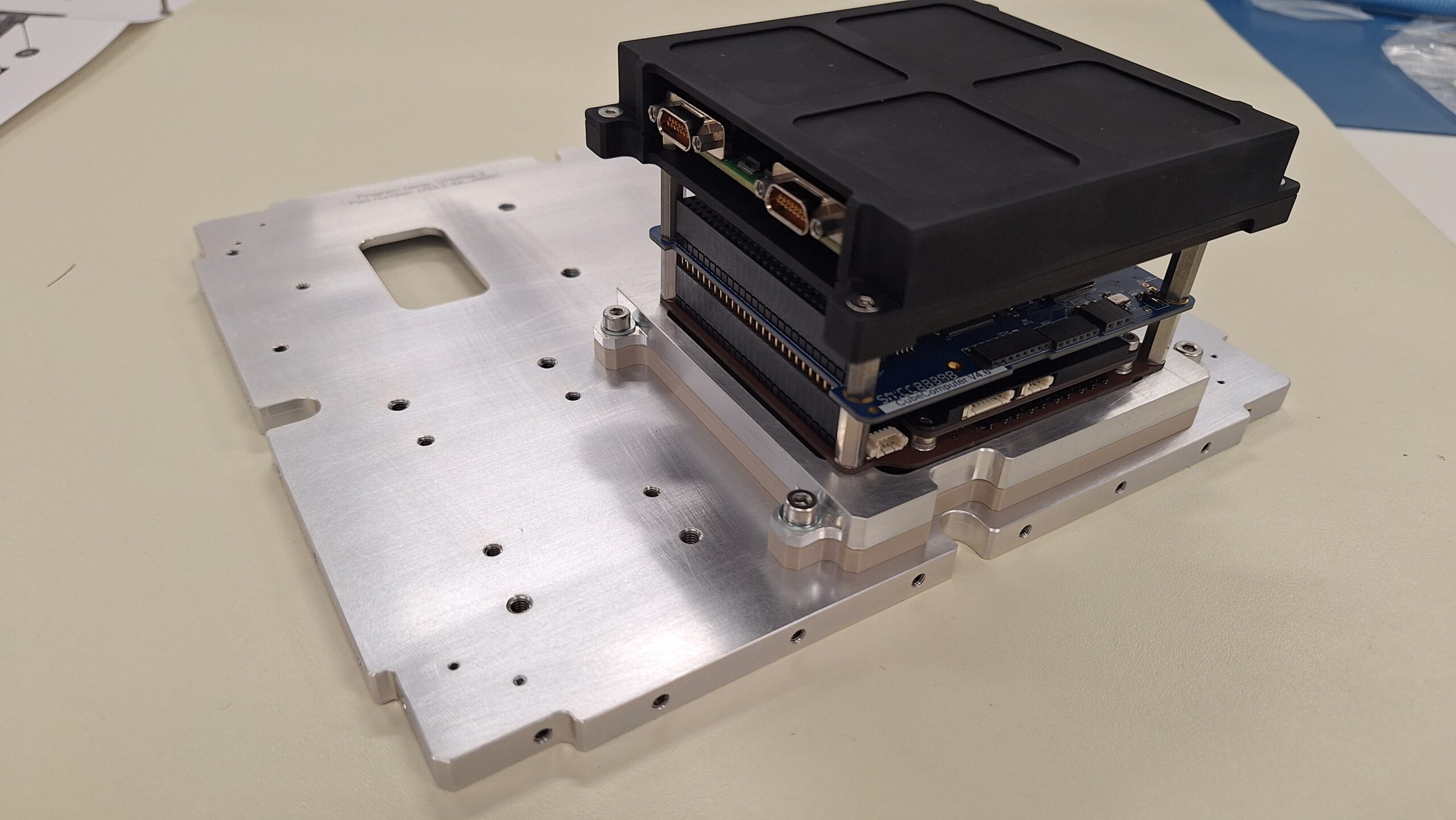

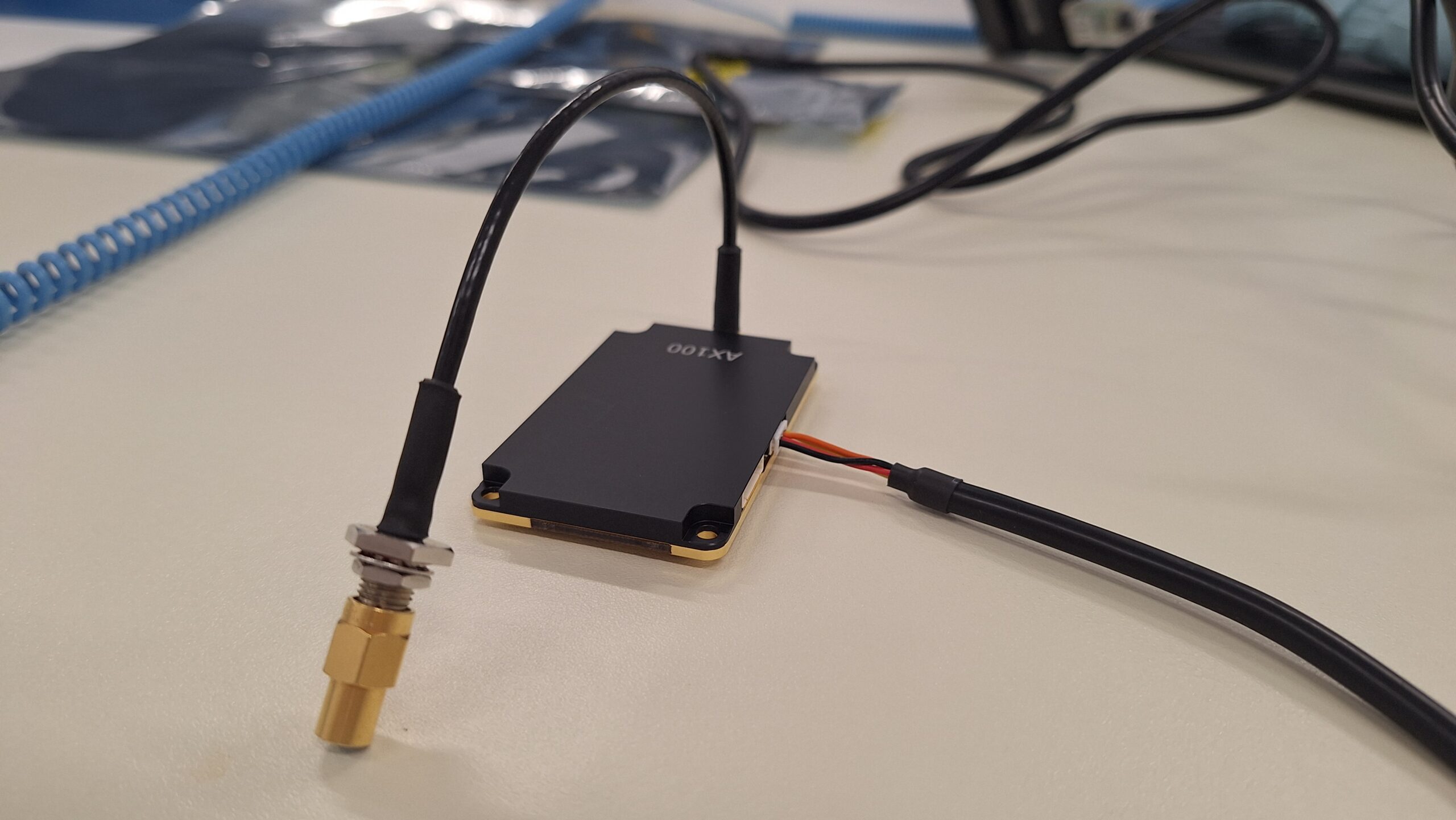

The satellite is equipped with two computers to monitor, control and manage the in-flight produced data. The first is the NanoMind A3200, manufactured by GomSpace, which includes the software to manage the operating modes, collect in-flight telemetry, process telecommands and communicate with the ground station via the NanoCom AX100 radio.

The second is CubeSpace’s CubeComputer V4.1, which includes the experiment management software. It communicates with the satellite payloads via analogue and digital lines. Digital communication was mainly via the I2C, SPI, and UART buses. On the other hand, the analogue interfaces were accessed via digital conditioning circuits and multiplexers.

Both computers, CubeComputer and NanoMind, communicate via the CAN (Controller Area Network) data bus. This is a communication standard used in critical environments such as the automotive and space industries.

The on-board software has been developed in the C programming language. The FreeRTOS real-time operating system and the LibCSP (Cube Space Protocol) communications protocol are also used. These are open source libraries widely used in the development of CubeSats.

The UPMSat-3 satellite software has been developed by the STRAST research group, composed of professors and students from the ETSIT and ETSIInf of the UPM. The National Institute for Aerospace Technology (INTA) has also collaborated in the development environment of the CubeComputer.

Communications

UPMSat-3 carries two flight transceivers on its mission: the first, manufactured by Gomspace, acts as a TT&C communications system in the UHF 437 MHz band, including the transmission of results from the various experiments carried on the satellite for in-flight demonstration. The second, manufactured by Hydra Space, is a payload that acts as a repeater with an uplink in the VHF band at 144 MHz and a downlink in the UHF band at 437 MHz.

The UPMSat-3 carries two antenna systems depending on the required frequency band: for the UHF band, the antenna system consists of 4 monopoles in a ‘turnstile’ configuration, suitable for the size requirements of the launcher. The antenna system operates in circular polarisation by feeding the monopoles with sequential rotation. To guarantee operations, 32 dB isolation is provided between ports. This configuration allows half-duplex operation on each transceiver, but both operating simultaneously; for the VHF band a monopole is used extending from the opposite plane to that used for the UHF satellite band.

The complete system is being designed by a joint team of IDR/UPM staff and professors from the radiation group of the ETSIT (UPM).

Electrical power

Mission experiments

The experiments for this mission focus on in-orbit technology demonstration, aimed at testing the performance of instruments and equipment under real operational conditions to establish their “heritage,” or operational credibility in space. Such missions are of high value to companies within the space sector, and the UPMSat-3 team, as part of a polytechnic university, has strategically oriented its activities in this direction.

UPMSat-3 will carry the following technological developments:

Photonic radiometers, developed by the Optoelectronics and Laser Technology (GOTL) group of the Carlos III University of Madrid. Current microwave radiometry from space is based on very sensitive observations over a wide range of frequencies, which requires low noise and/or broadband receivers. To achieve high sensitivity with currently available equipment requires cooling systems at cryogenic temperatures, which are very complex and heavy. Alternatively, broadband detection or very long observation times can be used. This payload is an innovative detection concept based on the conversion of microwave signals to the optical domain using crystalline ring resonators. By applying this concept, and avoiding active electronics, a wide frequency range can be covered at room temperature (without the need for cryogenics), improving radiometric resolution even in narrow spectral bands. This sensor concept would be suitable for a wide range of end-use applications, such as climate prediction, atmospheric observation or millimetre-wave astrophysical detection. It is intended to be able to make observations with sufficient continuity to derive a cosmic map of the microwave background, which also requires advanced attitude determination and control on the platform.

A miniaturised communications transceiver, developed by HYDRA Space. This equipment will perform dual UHF and VHF communications for its future use on PocketQube satellites. This device will allow for further collaboration with the radio amateur community, serving as a repeater for voice communications between ground stations and as a TTC unit through the implementation of a STORE-AND-FOWARD communications/messaging system.

Hold-Down & Release Actuator (HDRA) type mechanism for holding and deploying solar panels, developed by OCCAM Space. It is based on shape-memory alloys and will allow both non-pyrotechnic deployment and easy system reset.

A miniaturized power system for small satellite, developed by DHV Technology.

A set of attitude determination and control algorithms developed by the IDR/UPM staff.

In order to achieve the ambitious mission objectives, the satellite operational time will be divided between the different experiments, considering their operational modes and the power available on the platform.

Another important part of the project is based on contributing to Citizen Science projects. To this end, the UPMSat-3 team intends to strengthen its collaboration with SATNOGS and the radio amateur community (through AMSAT) with a twofold purpose: first, the aim is to transmit all UPMSat-3 data on amateur radio frequencies, so that they are accessible to the entire community. The decoding codes needed to transform this telemetry into real magnitudes will also be published openly, so that they can be used for scientific and educational purposes; and second, this collaboration will allow data to be obtained from the satellite at different geographical positions, which in turn will allow the IDR/UPM and its collaborators to fulfil the mission objectives (evaluation of determination control codes and attitude control, determination of the cosmic microwave background, etc.).

Integration and testing

The AIT (Assembly, Integration and Testing) activities are carried out at the IDR/UPM facilities at the Moncloa campus and at the Montegancedo campus.

The verification tests will ensure that the satellite’s systems and equipment will survive the launch and will be able to operate in the extreme conditions encountered in space (vacuum, extreme temperatures and radiation).

For this purpose, all systems undergo a verification process consisting of two main parts:

- Functionality and performance tests

- Environmental testing

In addition, verification testing is performed at several levels: at equipment level, at sub-system level (consisting of one or more equipment), and at satellite level (for qualification/acceptance of the final system).

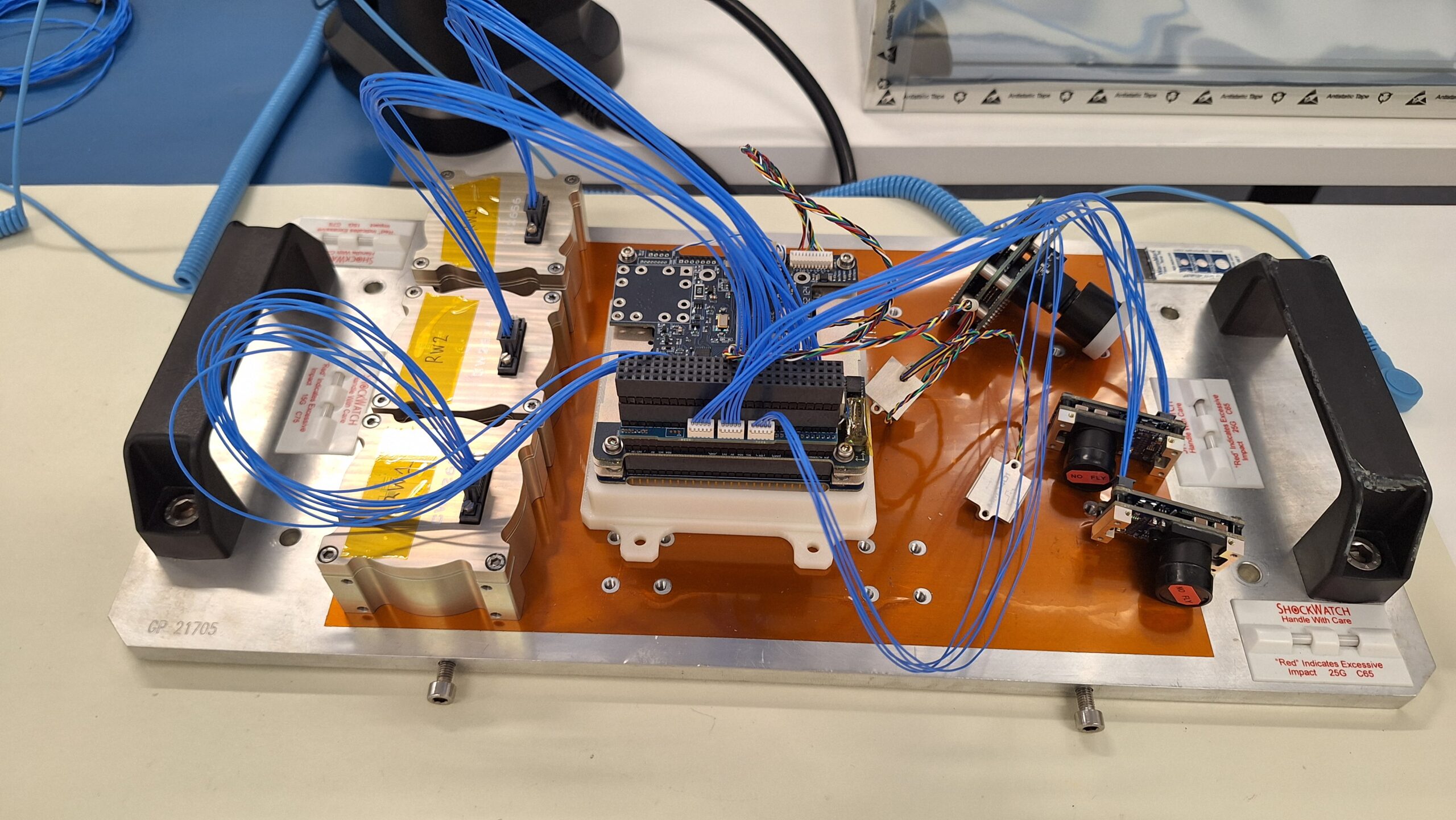

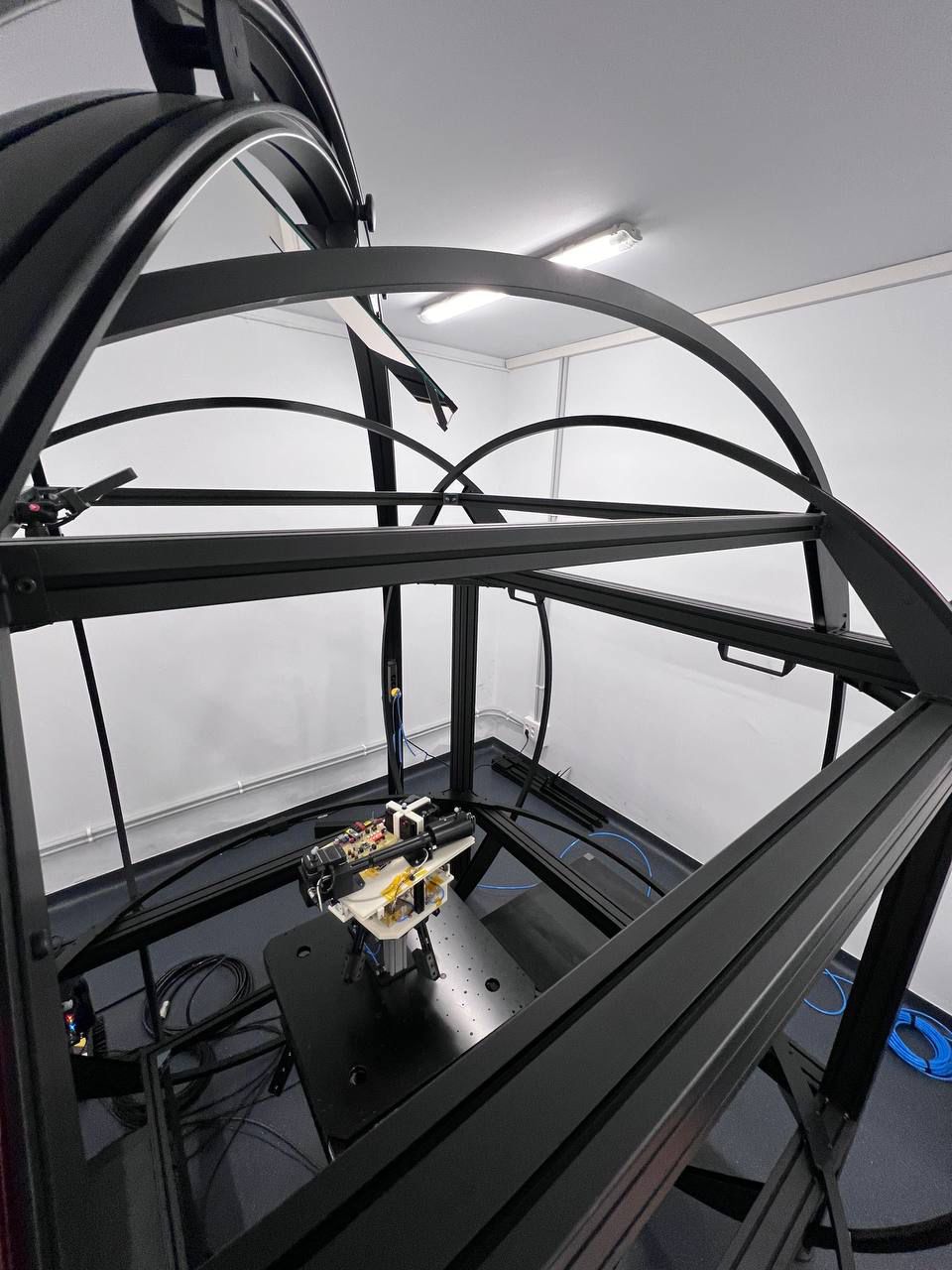

ADCS testing

The ADCS system tests focus on replicating the system activation and commissioning procedures to validate, step-by-step, the system configuration, the sensors readings and overall functionality.

The test campaign is performed incrementally, starting with the basic control and determination modes, to integrate in successive steps new sensors and actuators as the correct operability of each component is ensured, until the full functionality of the system is reached.

The tests allow to confirm that the system is correctly configured, and to gain experience in future satellite operations. During the tests, telecommands are sent to the system and data are collected as if the satellite were in orbit, with the added advantage of being able to directly compare the sensor measurements with the actual behavior of the system.

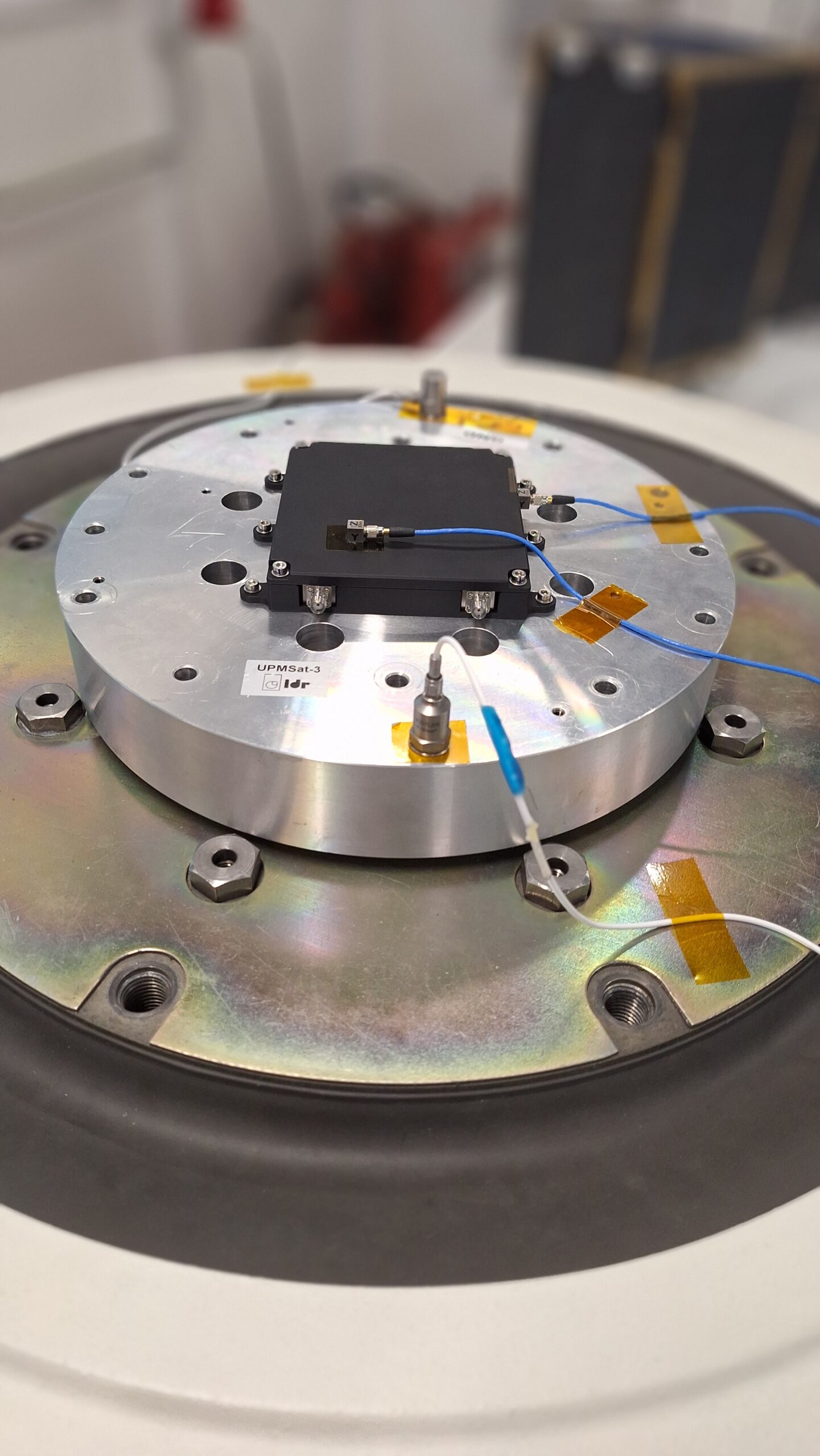

The success of the campaign has been possible thanks to the IDR/UPM Attitude Test Bench, an advanced tool in the simulation of attitude determination and control systems. This facility represents a very significant improvement in the testing of this type of system, leading a step forward with respect to simulation-based verifications, or isolated tests carried out at component level. The test bench system allows the recreation of a relevant space environment to simulate the actual conditions that the satellite will face once in orbit.

The Attitude Test Bench includes a flotation system based on an air-bearing, which simulates the free movement of the satellite in space. It also has a Helmholtz coil structure to generate a controlled magnetic field, and a series of simulators that ‘trick’ the sensors on board the satellite. These include a star simulator, a solar simulator and a GNSS signal simulator. This equipment allows testing of attitude control systems for satellites, from small 1U CubeSats to systems designed for satellites weighing up to 100 kg.

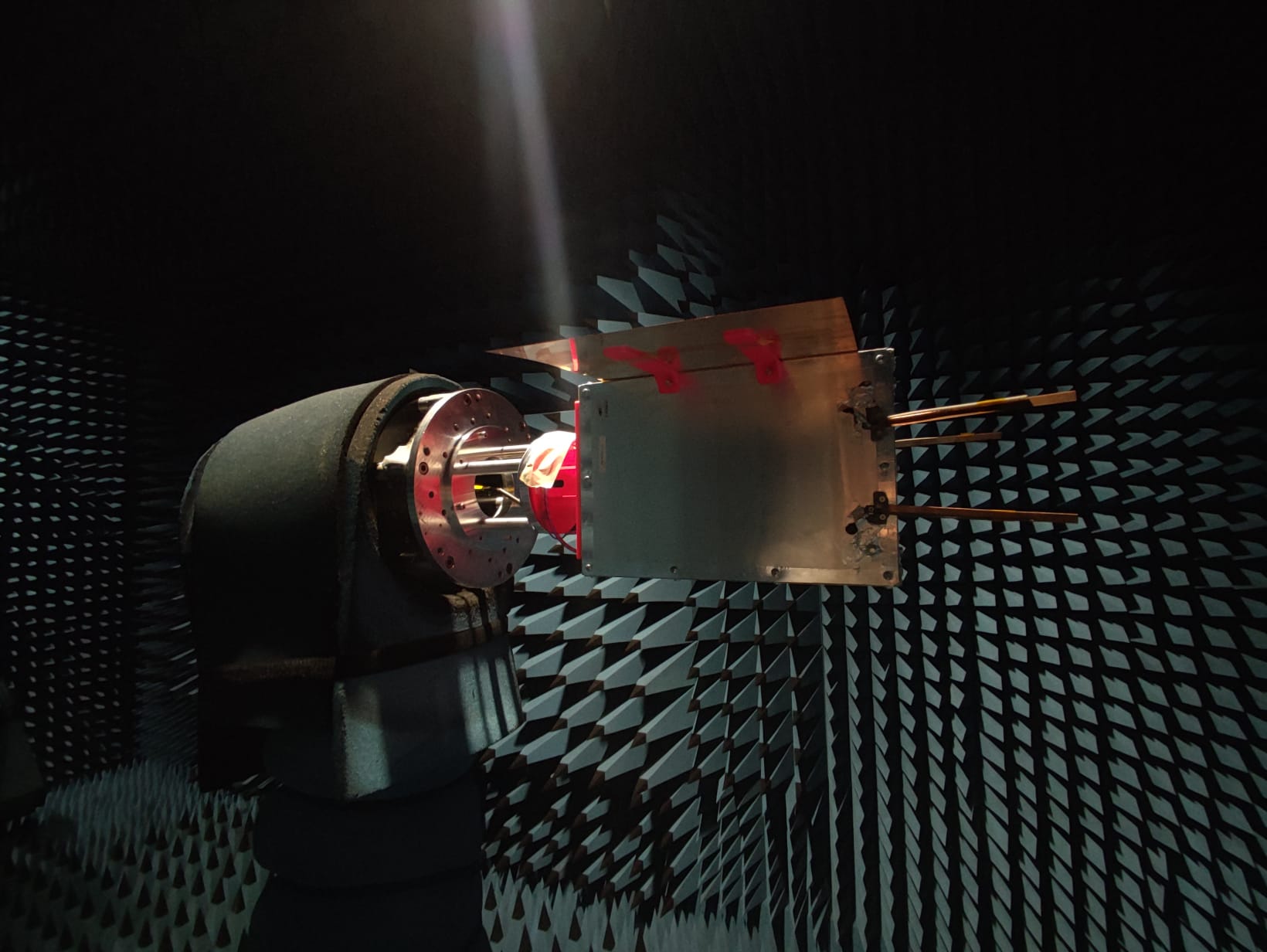

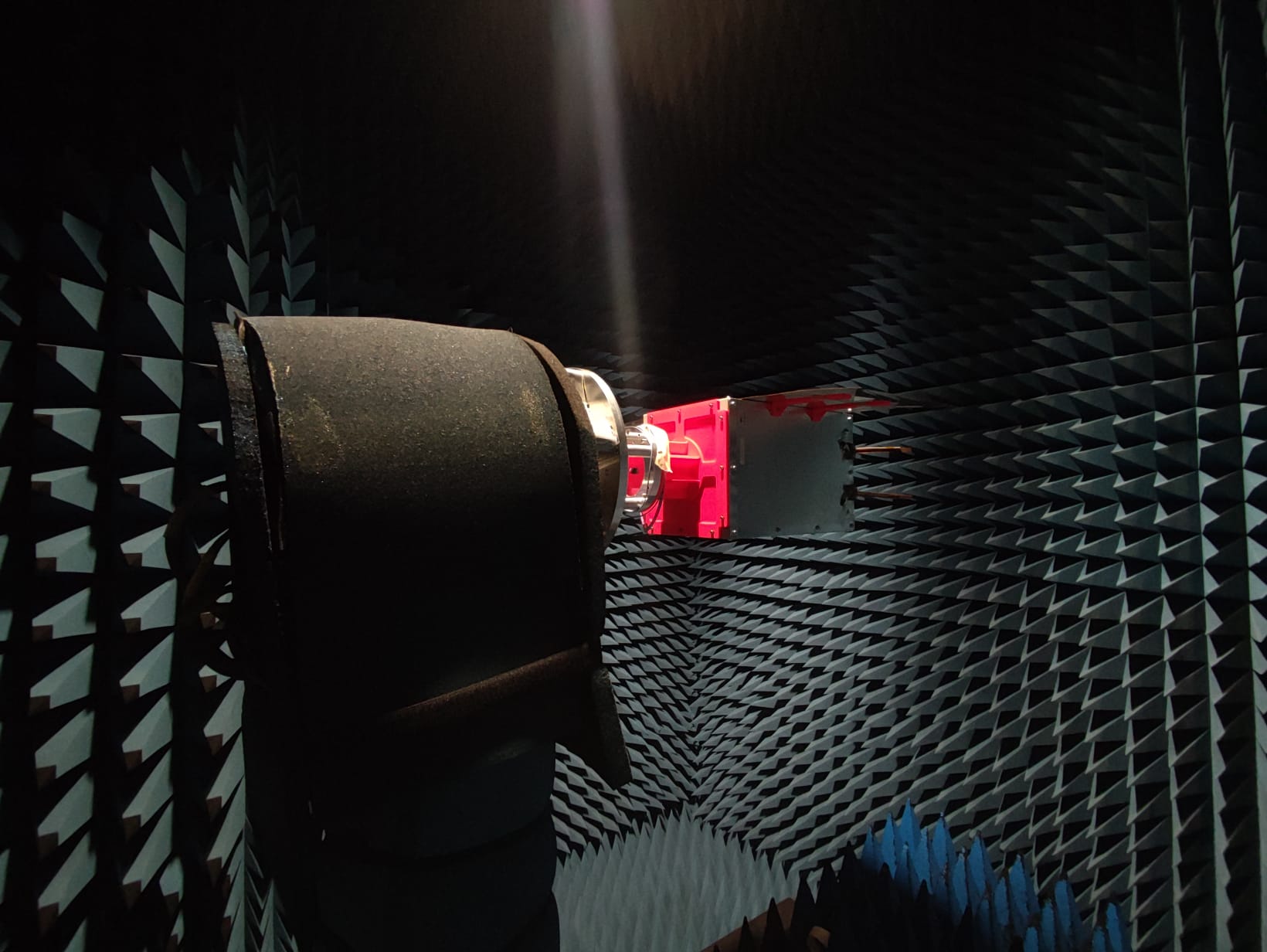

Hybrid-balun system testing

The hybrid-balun is a power supply network capable of isolating the two transceivers on board UPMSat-3, which operate in the same UHF band (436 MHz), since the operation of each of them is detrimental to the other (the radiated power of any of them is higher than the maximum power received from the other).

This system has been designed by staff from the ETSII and ETSIT of the Universidad Politécnica de Madrid, and has been qualified for flight at the IDR/UPM environmental testing facilities on the Montegancedo campus.

Antenna characterization testing

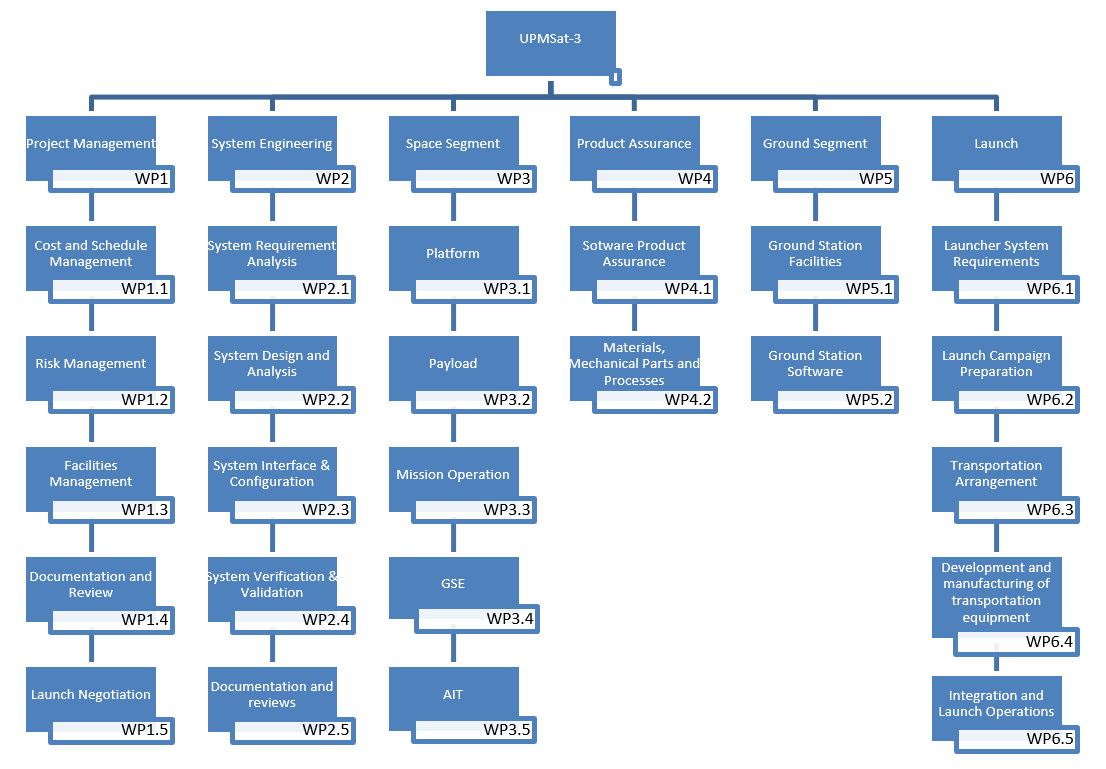

Project Management

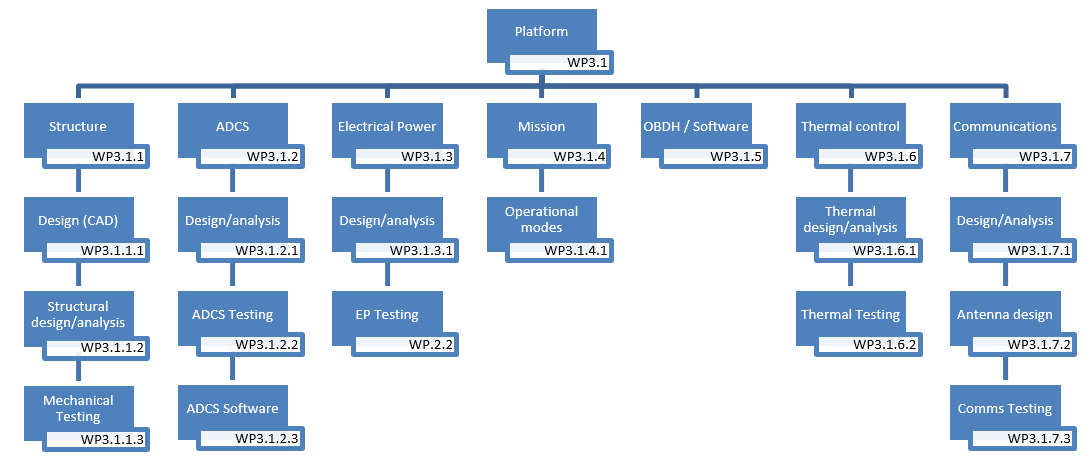

In order to carry out this project and organise as far as possible the large team of people involved, a certain hierarchy has been introduced by areas of activity, providing it with the necessary flexibility required by a university organisation.

The team responsible for the development of the UPMSat-3 satellite is led by a manager who is accountable to the sponsoring organisations and institutions and a set of work teams (articulated around the work packages defined in the project) coordinated by a system engineer. The work teams, consisting of one, two or three professors and several students, are responsible of the different subsystems with a flexible composition that considers the mobility and availability of staff in a university environment, and the specific needs of the project at the various stages of its implementation.

The following table shows the distribution of the human team currently participating in the execution of the project.

Staff participating in the UPMSat-3 project by categories and schools of the Universidad Politécnica de Madrid at the end of 2024.

Education and training

The UPMSat-3 mission has a strong educational character. It allows to continue with lines of educational innovation focused on methods such as ‘Project Based Education (PBL)’ or ‘Research Based Education (RBL)’, and like its predecessor, it will constitute an extremely valuable tool to complement the training of students of the UPM’s bachelor’s and master’s degrees. These initiatives will also be framed within the INNAERO Educational Innovation Group (Educational Innovation Group in Aerospace Engineering), consolidated since June 2022 and formed by professors of the IDR/UPM.

El programa UPMSat-3 está siendo utilizado para la formación de alumnos del Máster Universitario en Sistemas Espaciales (MUSE), realizando prácticas, trabajos dirigidos, casos de estudio y trabajos de fin de máster.